CS2RS-D507 Modbus stepper driver - 50V/7A - Closed loop

Driver for 2 phase stepper motor

CS-M... series (with 1000 to 5000 ppr encoder).

1.0 to 7A / 20 to 50 VDC

Closed loop

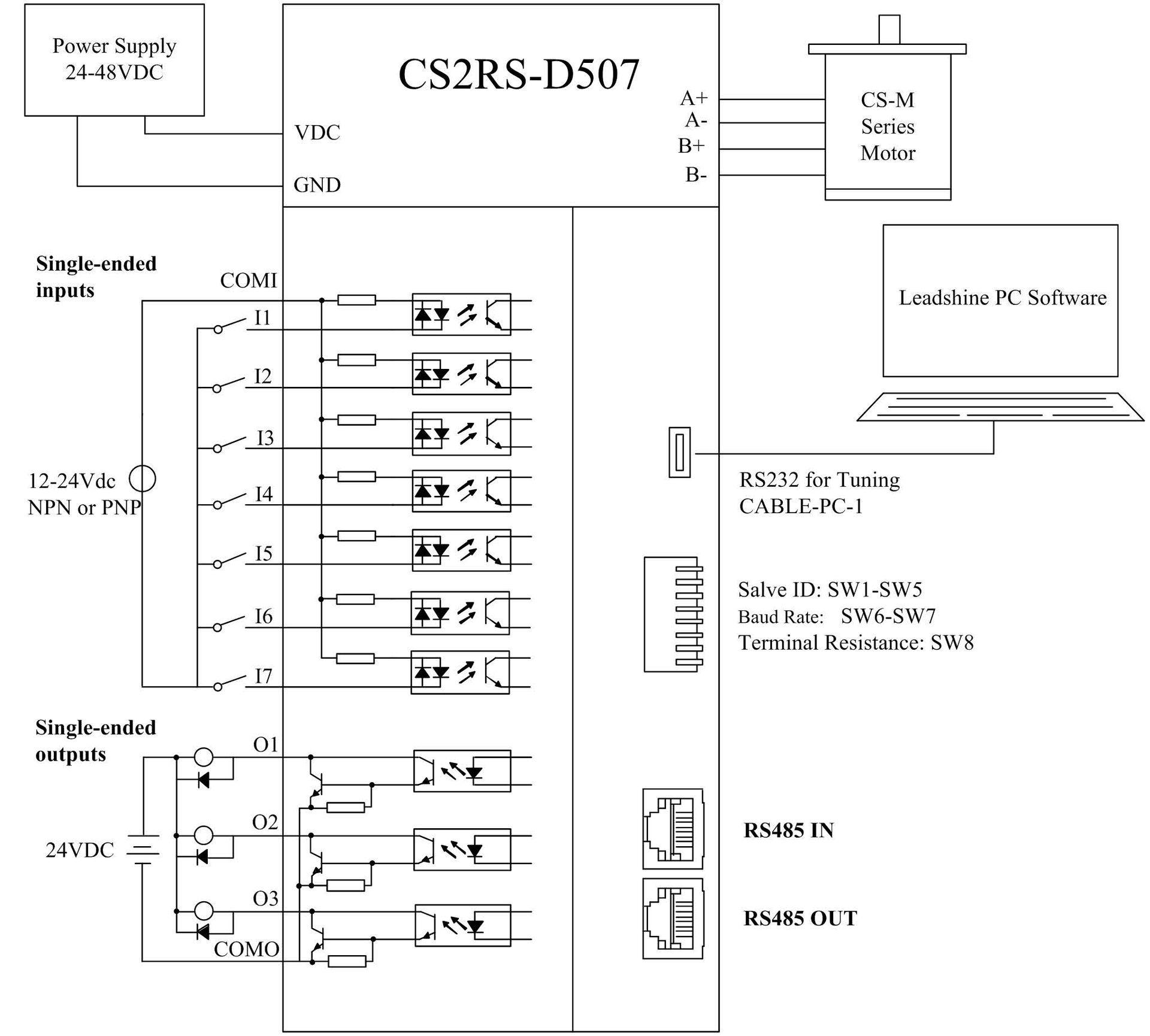

Modbus RTU bus (RS485)

8 switches for ID configuration

7 programmable inputs

3 programmable outputs

Tuning on PC via RS232 link

Product Documents

Internal Reference:

CS2RS-D507

CS2RS-D507 digital microstep driver

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Introduction | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The CS2RS series offers closed-loop stepper drivers based on the standard Modbus RTU protocol, using RS485 communication to network up to 31 axes, built-in PR function with 16-segment position table (PR mode). They can not only solve the problem of step loss in the open-loop stepper system, but also avoid the need for additional controllers in most point-to-point applications, to greatly improve the system reliability and reduce the costs. The CS2RS series also supports teach function, position profile, velocity profile and homing operation modes. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Applications | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Usable with NEMA 17, NEMA 23 and 34 size motors, this driver is particularly recommended for 2-phase motors of the CS-M... series of the SOPROLEC range, having an integrated encoder with a resolution of 1000 to 5000 pulses per revolution. Parameter setting via RS232 serial link allows the driver settings to be adjusted optimally. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

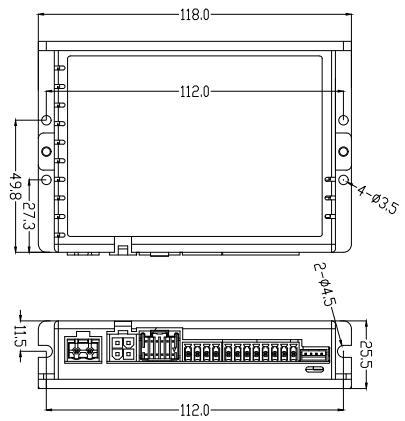

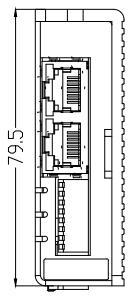

| Mechanical specifications (Unit: mm, 1 inch=25.4 mm)Dimensions: 118*79.5*25.5 mm Weight: 0.65 kg Operating temperature: 0-50℃ (32F – 122F) Storage temperature: -20℃-65℃ (-4F – 149F) Tolerated humidity: 40-90%RH Vibrations tolerated: 10-55Hz/0.15mm Mounting: Vertical or Horizontal |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pin assignment and description |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

CN1 - Input Power Connector

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

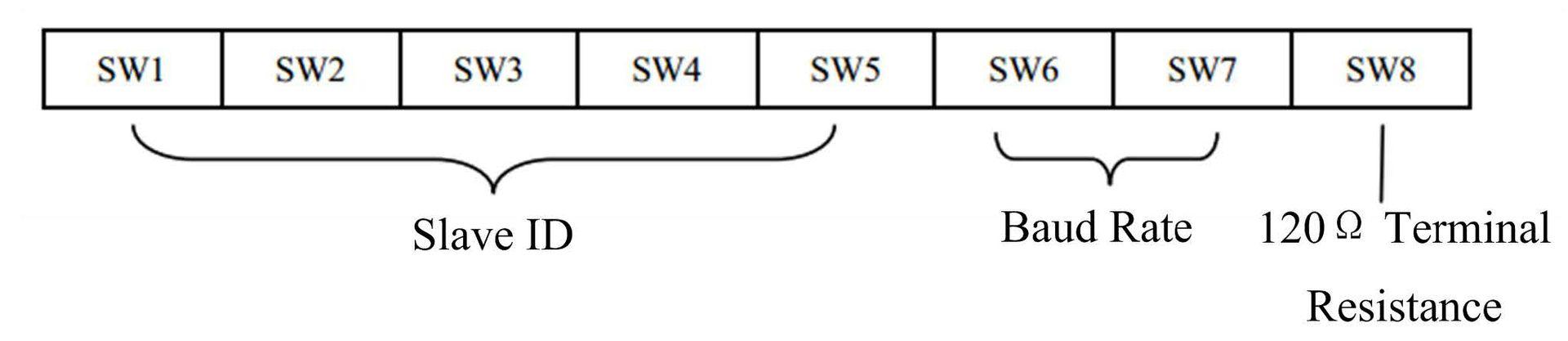

DIP Switches

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Configuration of the slave position of the driver: SW1 to SW5

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Baud Rate : SW6 -SW7 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Typical Connections |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Logiciel de paramétrage Leadshine Motion Studio V1.49 :

https://www.leadshine.com/upfiles/downloads/4f2e3904b60df00acb75d9cd2ae65491_1702632536136.zip

Accessories

Specifications

| Brand | Leadshine |

| Inputs | 7 |

| Outputs | 3 |

| Min. Voltage | 24 V |

| Max. Voltage | 50 V |

| Max. current | 7 A |

| Resolution setting | Tuning software |

| Configurable | via RS232 cable |

| Interface | Modbus RS485 |

| Current setting | Tuning software |